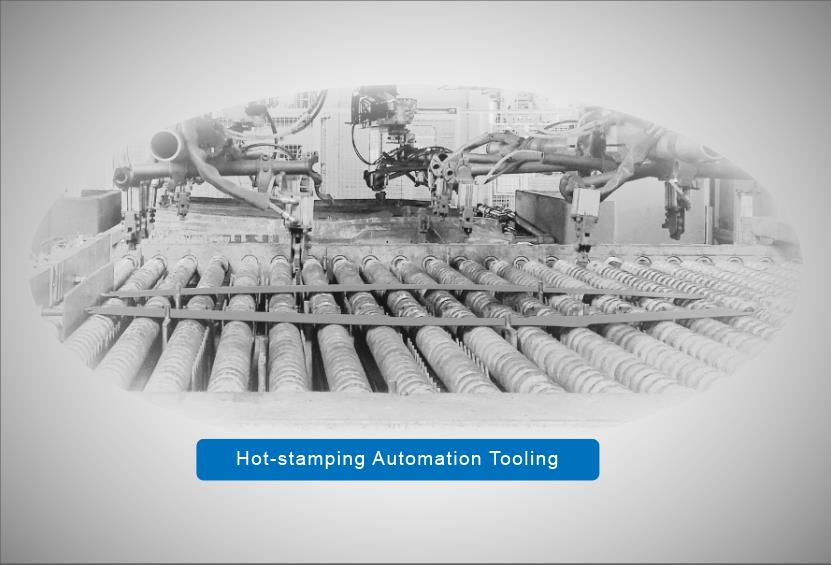

Hot-stamping Automation Tooling

Hot-stamping Automation Tooling

Hot stamping is often called stamping hardening technology. First of all, the initial strength of 500 ~ 600 mpa high strength plate heating to 880 ~ 950 ℃,

and then into the internal cooling system with the mould stamping, and under pressure, with the cooling speed of 20 ~ 300 ℃ / s rapid quenching cooling,

due to austenite into martensite, parts strength greatly increased, can produce a strength of 1500 mpa stampings.

The common hot forming production lines are box furnace and roll furnace production lines. Box furnace production line is more used for mold testing,

and roll furnace production line is used for mass production.

The feeding of the hot forming end pick up device adopts high temperature resistant pneumatic clamp or hook clamp, which can directly clamp 950° high

temperature red steel plate. It can be clamped vertically or horizontally. The clamp can be configured with material detection and double material detection

sensors, used for detection equipment to grasp the workpiece when monitoring.

The feeding end pick up adopts high-temperature resistant magnetic sucker, and the magnetic sucker of Ya Science and Technology adopts the design of

pneumatic driven permanent magnet to grab and release the steel plate. Compared with the traditional vacuum chuck, the magnetic chuck can absorb

irregular surface products and perforated steel plate, and can be used in high temperature environment (< 200℃).

Since its establishment, UYA technology has successfully delivered more than 500 sets of thermal forming end pickers.